3DEXPERIENCE World Makers Stand: Jade Wilson

I was honoured to attend 3DEXPERIENCE World 2025 back in February of this year and celebrate 30 years of SOLIDWORKS! I have been using SOLIDWORKS myself now since 2009, so I found it fitting to showcase some of my work on the makers’ stand that could only be achieved with the help of SOLIDWORKS.

If you attended the conference this year in Houston, you may have seen some of my ceramics at the Makers stand. I showcased the crystal tableware that I designed and produced while studying for my master’s degree at university in 2016. I used SOLIDWORKS for many steps in the design and production process, as well as a way of planning and visualising the final product.

Starting from the beginning, I used SOLIDWORKS to model my tableware, you can see the full process in a tutorial here. Modelling my design in SOLIDWORKS first allows me to test out designs in many different iterations quickly. This is a very powerful tool when it comes to ceramics; more traditional ways of designing and making in ceramics can take many tries and fails to get to a final piece, but by using SOLIDWORKS, I can speed up this process and ensure that I’m happy with the design before committing to the making stage.

From here, I can use SOLIDWORKS to plan the plaster mold of the piece to determine how many mold parts I will need, and also where the mold seams should be. You can see the processes I used for planning the mold in another tutorial here. Again, looking back to the traditional way of producing ceramics, you would have to do all of this by eye and hope for the best, but SOLIDWORKS took some of that pressure away and allowed me to test out my model for undercuts and plan my design before creating the mold.

From here, I can use SOLIDWORKS to plan the plaster mold of the piece to determine how many mold parts I will need, and also where the mold seams should be. You can see the processes I used for planning the mold in another tutorial here. Again, looking back to the traditional way of producing ceramics, you would have to do all of this by eye and hope for the best, but SOLIDWORKS took some of that pressure away and allowed me to test out my model for undercuts and plan my design before creating the mold.

Taking my ceramics knowledge, I decided to model feathers in SOLIDWORKS, 3D print them using 3DPRINT UK, and make a plaster mould of them. This could then be press molded with air-dry clay to create feathers for the wings. Plaster is the best mold material option for clay, as it is porous, so it helps to remove water from the clay, making it easier to remove cleanly from the mold. Thank you to all of those who came over to the stand and contributed to the wings, or just had a conversation about the process.

The Wings community build was made possible by an amazingly talented group of people, including Chinloo and Sal from Our Next Make, Matt and Jessie from The Mad Scientist Workshop, Luke and Karen from Orbital FX, and Christian and Sanket from Bowhead, and finally the Re3d team. This group of people is incredibly talented and passionate about passing on their creative knowledge with the SOLIDWORKS community, but when they all come together, they make magic!

The final set of wings turned out beautifully; it truly captured a moment where all attendees were able to leave a part of themselves behind at the event and capture a photo opportunity of themselves in front of the final wings. If you didn’t have a chance to visit the makers’ stand this year, I wouldn’t definitely add it to your schedule next year, where we will all meet up back in Houston!

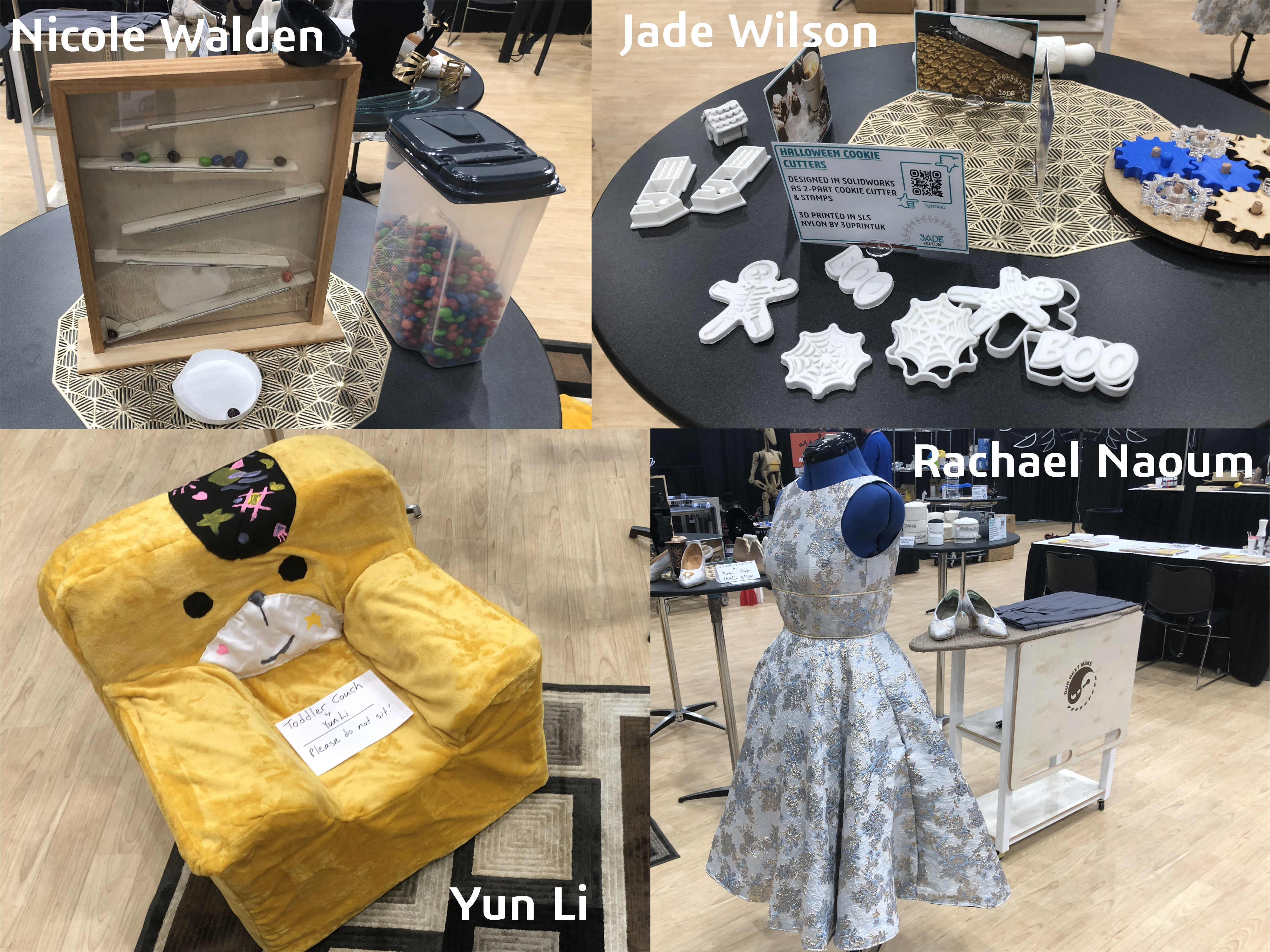

Finally, as I mentioned I exhibited alongside some incredible women in the industry as part of the Dames of Design section of the Makers stand, you will have seen work by SOLIDWORKS Product Definition Team engineer Rachael Naoum, mechanical engineer Nicole Walden, and SOLIDWORKS User Experience Design Specialist Yun Li, all brought together by Director of UX SOLIDWORKS Chinloo Lama from Our Next Make. Here we showcased some of our,own projects where we used SOLIDWORKS to create some of our maker projects. From dresses, shoes and jewelry, to toddler furniture, 3D printing, ceramics and a sweets dispenser, it had something for everyone.

We’re hoping to come back next year, bigger and better, to share even more from Women in Engineering.

A reminder for all women attending 3DEXPERIENCE World 2026: this year, we will have several dedicated sessions exclusively for women. Join us for the Women in Technology panel at 1:30 PM CT on Tuesday, February 3rd, in Room 342BE. Don’t miss this opportunity to join us for this unique session dedicated to the issues faced by women in technology fields. Register today!

You can also learn more about Jade in this blog post.