Using SOLIDWORKS and 3D Printing to designing Custom LEGO Wall Mounts

One of my favorite things about combining engineering tools with my hobbies is finding creative ways to display the things I love. Recently, I’ve been diving into using SOLIDWORKS and 3D printing to design custom wall mounts for my LEGO sets, and Being a SOLIDWORKS champion I thought, why not show you how I did it.

Instead of just letting these sets sit on a shelf, I wanted a cleaner, more unique way to showcase them. Something that not only saves space but also highlights each build. Here’s how I approached it:

LEGO Speed Champions Car Mount

The first project I tackled was creating a simple mount for my LEGO Speed Champions cars. Using SOLIDWORKS, I designed a bracket that securely supports the model without drawing attention away from the build itself. It’s a simple model that after a few measurements I had a final 3D model. Once printed, it was a perfect fit and gave me a great sense of how versatile custom mounts can be for my car collection.

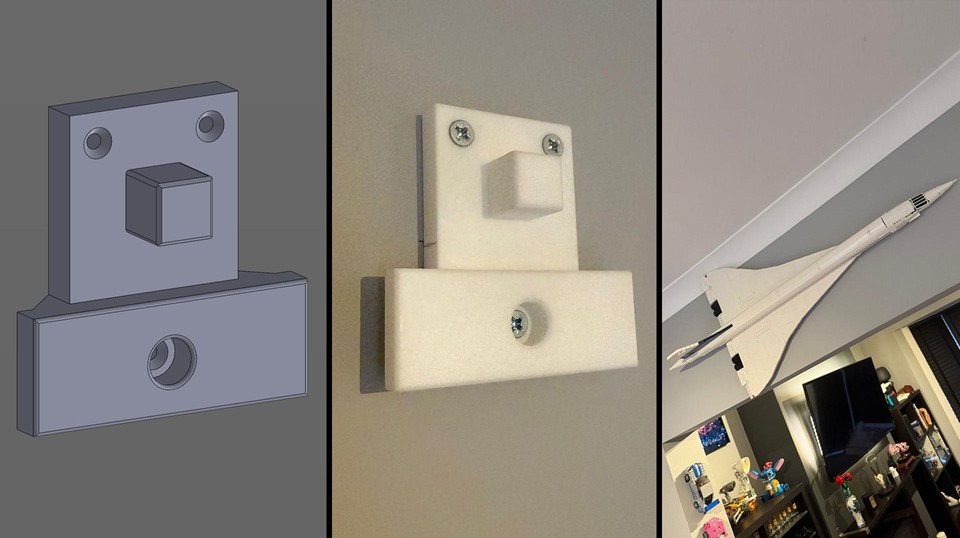

LEGO Concord Mount

Next up was my LEGO Concorde set. This one posed a challenge because of its size and sleek design. I wanted the mount to hold it safely while still keeping the plane’s profile clean against the wall. Using SOLIDWORKS I created a custom mount that was inspired by the table stand that you build with the set. Just turned 90 degrees and some extra support to distribute the weight into multiple contact points. Pair this with a strong SLS Nylon 3D printed part, I ended up with a solution that looks almost like it’s floating.

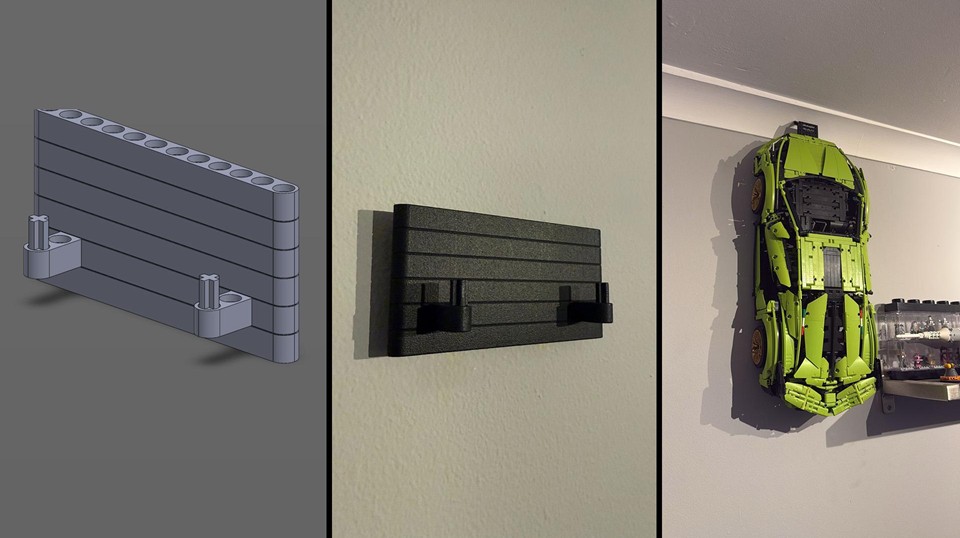

LEGO Lamborghini Mount

Finally, I worked on a mount for my LEGO Lamborghini, one of my favourite Lego sets to display. For this, I wanted something that emphasized the LEGO Technic pieces the car is built from. The mount had to be strong and precise, ensuring the car could be displayed securely against the wall and the mount had to be hidden. I couldn’t use the same style mount as I did for the champion models due to the weight and the strain put onto the wheels. I researched online how some of the acrylic mounts were designed to attach to the model. I located the pins that were used and started from there. In SOLIDWORKS i designed the mount to look like LEGO Technic pieces stacked with some keyhole slots at the back. It was then printed in SLS Nylon and dyed black. The result was not only practical but also gave the Lamborghini a gallery-like presentation.

Why I Love This Approach

Using SOLIDWORKS gives me full control over the design process. I can model each mount exactly to the dimensions of the LEGO set using the most basic design features like extrude and cut boss, patterns and finish with fillets and chamfers to complete the look. Then bring it to life with 3D printing technologies. Even if you don’t have a 3D printer you can use 3D printing services like 3DPRINTUK to print the parts for you at an affordable price.

It’s incredibly satisfying to see these mounts go from a digital sketch to a physical piece that transforms the way my LEGO sets are displayed. Plus, it adds that extra layer of personalization—every mount is tailored to the set it holds and they are one of a kind.

If you’re into LEGO and have access to 3D printing, I highly recommend giving this a try. It’s a fun project that blends creativity with engineering and gives your LEGO collection the display it deserves. It even frees up some shelf space for even more sets!