The Science Behind the Perfect Edge: Inside Sparx Hockey

The Challenge

Develop a next-generation automated skate sharpener with extreme precision and performance requirements, while reducing costly prototype cycles.

The Solution

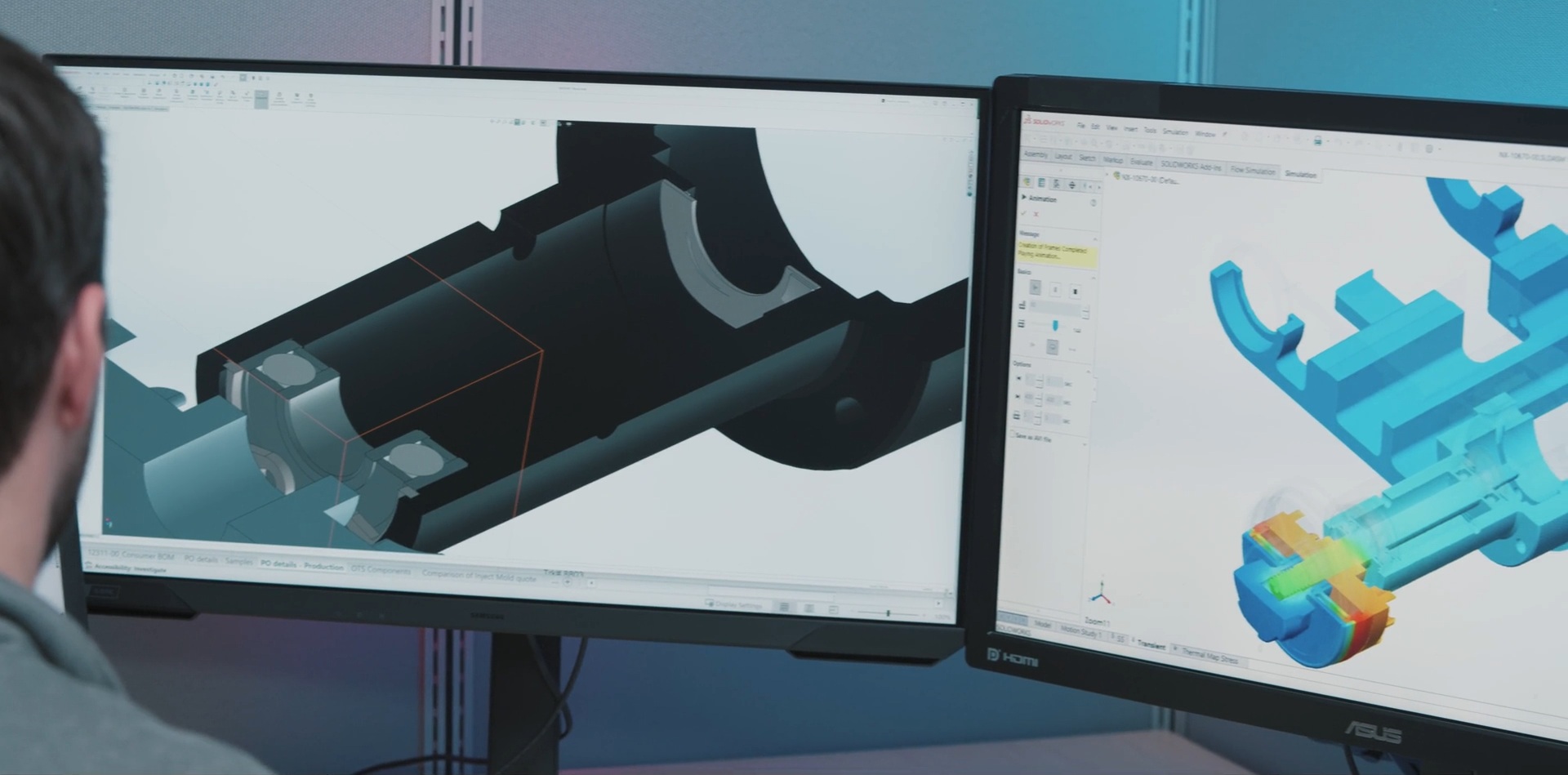

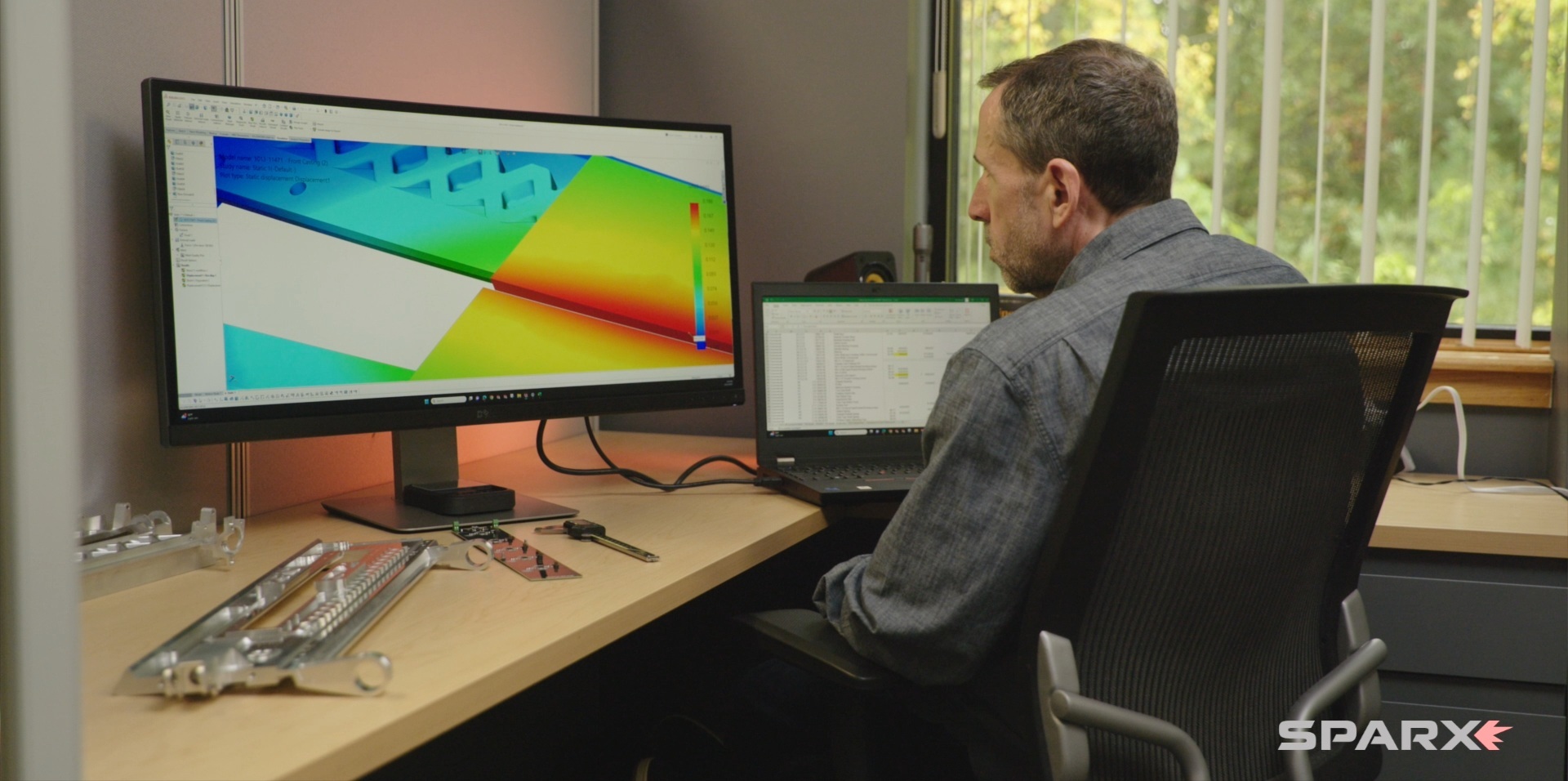

Use SOLIDWORKS Design and SOLIDWORKS Simulation to reimagine product design, optimize structural performance virtually, and resolve critical issues involving stiffness, load transfer, and kinematics before building physical hardware.

The Results

- Minimized expensive prototype iterations

- Increased engineering accuracy and confidence via simulation-driven design

- Consolidated multiple extruded parts into a validated single casting

- Delivered a consistent, pro-level sharpening system used by more than 100,000 customers, including NHL teams

Standing in line at an ice rink, bike shop, or hockey equipment store on a Saturday morning, waiting to get your kid’s skates sharpened before a game, instills only one feeling: Hope the sharpener is skillful and has a steady hand today. Generations of hockey parents and players have accepted this ritual. It’s tradition. Skate sharpening also tends to be inefficient and fundamentally imprecise. For Sparx Hockey Founder and CEO Russ Layton, that disconnect wasn’t wistfully nostalgic. It was a problem begging for engineering innovation.

Layton grew up skating in New Jersey, experiencing firsthand how good skate edges are critical for hockey performance, and how unreliable the sharpening process could be. He endured time-consuming weekly trips to pro shops and even resorted in his youth to once sneaking a bench grinder into a hockey camp dorm to sharpen skates. Even so, years later, he found himself doing the same thing his parents did: Driving to a sharpener shop, standing in line, and hoping for the best.

Annoyance is rarely enough to build a company. But frustration paired with engineering experience? That can spark something new. Layton had years of experience building products in the medical device industry, where tolerances matter, failure modes are analyzed, and design loops demand rigor. After he was laid off from his medical device day job, he applied that mindset to an overlooked corner of the hockey world.

“We came into the market to create a product that would allow anyone to have pro-level accuracy to sharpen a skate at home,” explains Layton. “The products that were on the market were very cumbersome, and they were dirty and dangerous. If we were going to disrupt this market and create a product that would allow anyone to sharpen a skate, we had to solve some really key problems.”

With an obsession for marrying the latest developments in engineering, design, and manufacturing with an unchanged-for-a-century process of skate sharpening, Layton started Sparx Hockey in 2013 to invent an automated at-home skate sharpening device.

Achieving Uncompromised Precision

Designing a skate sharpener is no small task. It contains roughly 300 individual parts. When the Sparx engineering team began developing a new generation of the machine, they had to rethink almost everything: the overall size, part placement, internal layout, and how all those components interact. Vice President of Engineering Dan Beaudet continues, “To be able to do [all that work] in three dimensions with a tool that can just move things around, especially in the early stages, is invaluable. I mean, I can’t imagine life as an engineer without SOLIDWORKS®.”

Because skate sharpening demands extreme precision, the challenges were significant. The difference between the two edges of a skate blade must be controlled within a few thousandths of an inch—less than a human hair. Even tiny variations affect performance, so the system must grind steel within extremely tight tolerances.

Layton had to be laser-focused on engineering because accuracy was not optional. From day one, the Sparx Sharpener had to have exceptionally precise component standards, from ultra-straight shafts to high-quality bearings, and every element had to meet that standard every time. “SOLIDWORKS Simulation helps us be smarter about our designs and do fewer iterations empirically,” he emphasizes. That approach saved time and money.

In addition, several parts in the sharpener—seven or eight individual extruded parts—were candidates to be consolidated into a single casting. To move forward with that approach, the cast version had to deliver the same structural performance as the original extrusions. “We were able to use [SOLIDWORKS] Simulation to design the final casting, ensuring a hundred percent that it would be as strong as the extrusion,” notes Layton.

Engineering Accuracy

There were many long nights in the garage, early prototypes, and rejections of seemingly clever ideas. In the end, they built a device anyone could operate, as straightforward as making a cup of coffee. “We turned what was this very artisanal, blacksmith-like process into a machine that’s as simple as a Keurig®,” says Layton.

When a skate is sharpened correctly, both edges sit perfectly level. But if the edges fall out of level—even slightly—one will feel sharper than the other. That imbalance can cause a skater to turn left with a strong grip but lose control, sometimes even fall while turning right. At the elite level, including the NHL, athletes immediately detect such imbalances.

Layton continues, “We use [SOLIDWORKS] simulation quite a bit here, because there are many really deep technical problems associated with our device, like structural integrity, key transfer, and kinematics.” The goal wasn’t to guess and build. The goal was to reduce the trial-and-error process entirely. SOLIDWORKS Simulation allowed the team to build fewer physical prototypes by optimizing design performance from the early stages of development.

The Hard Work Pays Off

Much has changed since those early days. What began as a prototype in Layton’s garage has evolved into a precision skate-sharpening system. Traditional sharpening depends on manual passes across a rotating grinding wheel, where edge quality varies with operator technique, pressure, and alignment. Sparx removes those variables. The skate is rigidly fixed in place, while a controlled grinding ring traverses the blade under constant load and programmed travel. The system maintains edge height, radius, and surface finish within tight tolerances to deliver consistent geometry every cycle. In three to four minutes, the blade exits with uniform edges. No skilled operator required.

There are over 100,000 Sparx Sharpeners in the market today. Both kids and adults love the product, including several NHL teams and former NHL players. “You can pull your skates right out of your hockey bag, throw them in the Sparx Sharpener, put them back in the bag, throw the bag in the car, and you’re on your way to the game or practice,” enthuses Sparx Hockey Vice President of Marketing Steve Jones. “It doesn’t get more convenient than that.” However, Sparx didn’t win just on convenience. It also won on consistent accuracy and control.

Innovation Continues

The success of the Sparx Sharpener has not changed the entrepreneurial mindset at Sparx Hockey. As Beaudet notes, the innovation will not stop: “We’ll continue to evolve the Sharpener. We’ll make it faster, lighter, and less expensive.”

It is remarkable to think that what started as a childhood frustration evolved into a precision instrument that automated a craft and stabilized a critical performance variable for hockey players. “Our company democratizes skate sharpening. It takes any hockey player or hockey family and allows them to sharpen their skates with pro-level accuracy, safely, and easily. Layton concludes: “Where your skates are touching the ice is the foundation of everything in hockey. If your skates are sharpened as they should be, you’re able to perform at your very best.”

Read the full Spark story here: http:www.solidworks.com/SparxHockey

If you would like to skate past your competition, contact your local SOLIDWORKS reseller.