Day Two of 3DEXPERIENCE World 2026: Catching up on the Action

It’s hard to believe that we are already on day two of 3DEXPERIENCE World 2026, and if you are here in Houston, the excitement is building around today’s General Sessions with a highly anticipated speaker, but the topic of the day is Artificial Intelligence (AI).

Pascal Daloz, CEO of Dassault Systèmes, kicked off things on day two of General Sessions. Pascal explained how SOLIDWORKS and Dassault Systèmes are redefining the future of engineering with its unparalleled community of the world’s most skilled and demanding engineers—those who design and build products that must work. As the definitive AI-first engineering software company, Dassault Systèmes leverages 40 years of industrial expertise to create impactful, science-driven AI solutions.

Next up, Pascal invited a heavy-hitter in the tech world, our special guest, NVIDIA Founder and CEO Jensen Huang, to the stage to discuss the ongoing partnership between Dassault Systèmes and NVIDIA to build the world’s most powerful industrial AI platform.

In partnership with NVIDIA, DS is empowering millions of engineers to design, simulate, and operate complex systems with greater speed, reliability, and scale than ever before. By harnessing the power of world models—built on physics, engineering, lifecycle data, and intellectual property—this collaboration transforms accelerated computing into actionable understanding.

Celebrating a 20-year partnership, Dassault Systèmes and NVIDIA continue to inspire the engineering community with groundbreaking innovations and real-world applications, showcasing the immense potential of their joint solutions through customer success stories and priority use cases.

This shared industrial AI architecture combines Virtual Twins and AI and is deployable at scale. Science-validated world models will position industrial AI as a mission-critical system of record, not a point solution. This Platform, accelerated by NVIDIA, grounded in science by Dassault Systèmes, expands long-term value creation across biology, materials science, engineering, and manufacturing through a new way of working: skilled virtual companions.

If you missed this fascinating discussion on the future of AI, you can watch it here.

You can read more details about this exciting partnership in this Dassault Systèmes blog post.

SOLIDWORKS CEO Manish Kumar also took the stage to share exciting updates and innovations. We also heard directly from AI-focused customers and discovered advanced AI features designed to save time, reduce manual effort, and enhance design precision. Together, we’ll align on shared goals and shape the future of design.

“AI is foundational to every industry. We’re growing so fast because everyone needs to build it. This is the beginning of a new industrial revolution. DS is the engine of that revolution.”

Delivering the Future: AI Virtual Companions in Design

Cloud technology is only as powerful as the people who use it. While processing power and chips provide the engine, the engineering community decides where that engine goes.

During Day two, we explored how “cognitive energy” is reshaping product creation. This is not about replacing the designer, but about empowering the “second wave” of innovators—you—to direct this energy efficiently. The focus has shifted from theoretical capabilities to practical, AI-driven tools known as “Virtual Companions.”

Major announcements were also made on AURA, LEO, Marie, and the integration of AI across the 3DEXPERIENCE platform, specifically within SOLIDWORKS and DELMIAWorks.

The Era of the Virtual Companion

We view AI as an expert partner, rather than an automated replacement. These Virtual Companions assist with ideation, design modifications, and simulations. They are designed to help you deliver projects on time, by removing the friction between your creativity and the final model.

This year marks a massive leap forward in how these tools will be applied to daily workflows.

Ideation and Structure with AURA and LEO

Great designs begin with curiosity. Protecting intellectual property is critical during the early stages of development.

Private Ideation with AURA

AURA operates directly inside SOLIDWORKS, allowing you to explore options and search for inspiration securely. Unlike open web tools, AURA keeps your searches private. You can iterate on concepts without revealing your ideas to the public domain.

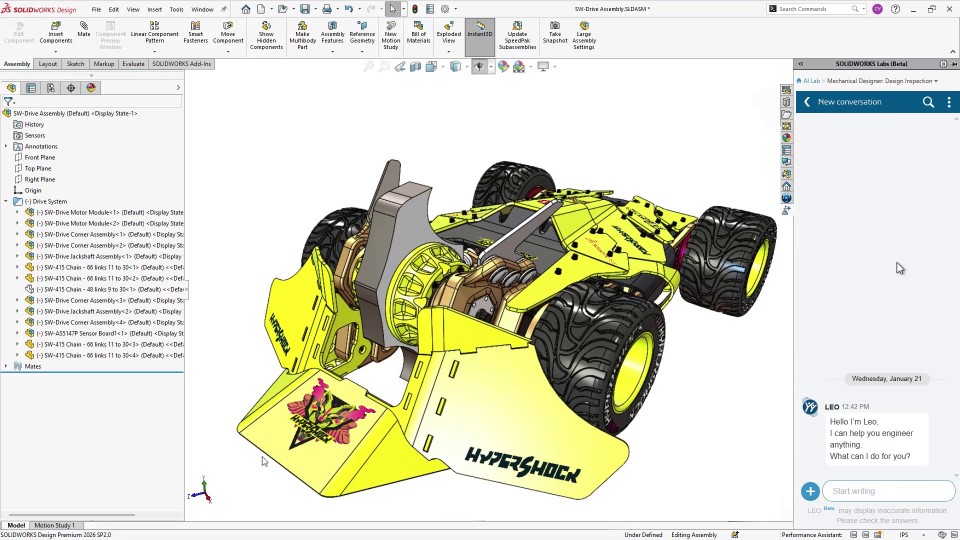

From Concept to Assembly with LEO

Once an idea forms, LEO helps bridge the gap between a concept and a tangible structure.

- Generative Assembly: You can use LEO to generate an assembly structure directly. This prevents you from starting from zero.

- 2D to 3D: We are removing barriers between inspiration and modeling. LEO can now assist in converting simple images into 3D meshes.

- Error Analysis: When design errors occur, LEO analyzes the problem and guides you through the fix, acting like an expert sitting at your desk.

Chatting with Your Data

One of the most significant advancements is the ability to interact with your model using natural language. Instead of navigating through multiple menus to find information, you can simply ask your assembly questions.

Queries like “How many parts do I have?” or “Which parts are made of aluminum?” receive instant answers. You can also execute broad changes, such as updating materials across an assembly, via text prompts. This shifts the focus from tedious manual steps to the bigger picture of design intent.

Extending AI Beyond Design

Delivering a product requires more than just a 3D model. It involves project management, manufacturing, and regulatory compliance.

Project Clarity with ENOVIA

Design challenges often stem from misalignment between people and plans. LEO now boosts ENOVIA Project Planner by summarizing status and surfacing risks. You can ask simple questions like “What is blocking this release?” to get immediate answers without digging through dashboards or spreadsheets.

Manufacturing with DELMIAWorks

For manufacturing firms, the work continues on the shop floor. We are bringing LEO to DELMIAWorks to streamline ERP and MES interactions. Instead of navigating complex forms, you can ask LEO for order statuses, shipping dates, or cost breakdowns. This removes friction between business data and production reality.

Scientific Simulation and Compliance

We are simplifying advanced tasks to make every user feel like a simulation expert. AI now assists in setting up complex scenarios, such as drop tests for medical devices.

Furthermore, regulatory compliance—often the most complicated aspect of the medical industry—is being streamlined. LEO can read complex government regulations and convert them into specific requirements. It can even assist in extracting quality and test documents, saving significant time and ensuring accuracy.

The Foundation: Data and Feedback

To use these next-generation tools, data must be structured and accessible. SOLIDWORKS is prioritizing the movement of data to the 3DEXPERIENCE platform to ensure it is ready for AI integration.

However, innovation is not solely defined by AI. Based on user feedback, we are delivering over 200 non-AI projects and enhancements this year. We listened to your “Top 10” lists and have implemented more than 30 specific requests to improve core functionality.

The future of design is not about automation replacing the craftsman; it is about the craftsman having better tools. AI is simply the newest, most powerful tool in your toolbox. Your creativity and perseverance remain the defining factors of success.

Dassault Systèmes and SOLIDWORKS are committed to building these tools to meet your specific needs. By integrating Virtual Companions into your workflow, you can focus less on the process and more on the product.

Customer Spotlight

Next up was Suchi Jain, the VP of Strategy and Business Development, who started with a question he often hears: Will AI replace engineers? He explains that he thinks that is the wrong question. Why?

“Because the best ideas? They’ve always come from people. From vision, intuition, and emotion. AI helps us go faster. Explore more. But you drive the spark.”

Suchit then welcomed three founders who’ve taken that spark and built extraordinary things—companies using AI not as the destination, but as a force multiplier for imagination

These founders included:

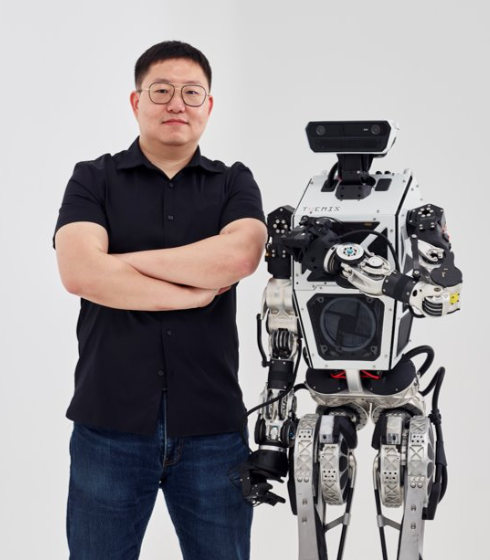

- Dr. Xiaoguang Zhang, the founder of Westwood Robotics

- Dr. Aadeel Akhtar, PSYONIC, the leader in advanced bionic hands for humans and robots.

- Russell Layton from Sparx

These companies are on the leading edge of how AI can be used to innovate and improve upon products quickly. All these companies came out of the SOLIDWORKS for Startups program.

Westwood Robotics

Next up was Dr. Xiaoguang Zhang, the founder of Westwood Robotics. Suchit’s first question was how Xiaoguang got started in robotics.

“I’ve been fascinated by humanoid robots for as long as I can remember. I was ten when I saw ASIMO walk for the first time, and I got absolutely obsessed. Then, in 2015, I joined the DARPA Robotics Challenge as a PhD student, but the moment that every humanoid robot I admired failed to finish even the simplest tasks was a wake-up call. Westwood Robotics grew directly out of that, a company that brings robots closer to people and turns humanoids into reliable teammates that help people.”

To deal with the high levels of mechanical complexity in robotics, Westwood Robotics relies on SOLIDWORKS Simulation to validate structural behavior and thermal performance early, before metal is ever cut.

“That lets us quickly stress-test design choices, catch weak points, and make informed tradeoffs around strength, deflection, heat, and reliability without burning time on repeated physical prototypes. We also use topology optimization to systematically remove unnecessary mass while preserving stiffness, which is critical when every gram affects dynamics, energy use, and control performance.”

PSYONIC

Suchit then spoke with Dr. Aadeel Akhtar, the founder of PSYONIC, the leader in advanced bionic hands for humans and robots.

Aadeel explained how the company’s flagship product, the Ability Hand, came to fruition:” I’ve wanted to build bionic limbs since I was seven years old. My parents are from Pakistan, and I was visiting there for one of the first times. That was the first time I met someone missing a limb. She was my age, living in poverty, missing her leg, and using a broken tree branch as a crutch. This inspired me to want to make advanced bionic limbs that were accessible to all.”

The Ability Hand is the fastest on the market, super durable, the first with touch feedback, and is covered by Medicare. The company now has close to 300 humans using it as a prosthesis, and over 50 robotics companies using it, including NASA, Meta, Amazon, Google, Apptronik, Mercedes-Benz, and top industrial, auto, and brain-machine interface companies.

When asked what’s next for PSYONIC, Aadeel said,

“Five years from now, I see robots as standard teammates in production and daily operations: humans set goals, handle judgment calls, and manage exceptions, while robots take care of physical, repetitive, or risky work consistently and safely. With the help of our robots, more tasks will be completed per hour at a lower cost per task, with humans focused on the parts that truly require human intelligence.”

The mission at SPARX is simple: Develop a next-generation automated skate sharpener with extreme precision and performance requirements, while reducing costly prototype cycles. To accomplish this, SPARX uses SOLIDWORKS Design and SOLIDWORKS Simulation to reimagine product design, optimize structural performance virtually, and resolve critical issues involving stiffness, load transfer, and kinematics before building physical hardware.

Russell feels that SOLIDWORKS is the company’s secret weapon in the engineering process. He cites its ease of use and ability to iterate through parametric modeling, and also optimizing the finest aspects of the components for the highest performance in the simplest parts, as invaluable. “SOLIDWORKS is how Sparx maintains its position at the forefront of innovation in our field.”

“I was a mechanical engineer, a hockey player, and a parent… and I had a naive disregard for the impossible (I was an entrepreneur ever since I was little), and I was looking for a problem to solve. And now I’m here today to talk about it… We sell products in 30 countries, performing well over 10 million sharpenings per year. Have well over 100K users – professional teams, universities, retail stores, ice rinks, and hockey families around the world using our products…It’s pretty amazing how our product has impacted skating sports so dramatically.”

Russell Layton

You can read a full case study on how SPARX is using SOLIDWORKS solutions to sharpen its own competitive edge here: http:www.solidworks.com/SparxHockey

Join us tomorrow when we celebrate the amazing SOLIDWORKS community.

Thanks to everyone who joined us today—or via the livestream! Be sure to tune in tomorrow morning for day three coverage here.