KingsBox Custom Gym Solutions: Delivered Fast and Built to Last

From humble beginnings in a garage to one of Europe’s leading fitness equipment manufacturers, the KingsBox story is one of vision, innovation, and determination. Founded by childhood friends Dejan Kobal and Luka Železnik in 2015, KingsBox now serves customers in 23 countries from a 3,000-square-meter production facility in Slovenia and has more than 40 employees. CEO and Development Lead Dejan Kobal notes, “We didn’t have any money, but we had a lot of time, so we decided to invest all our time into this huge project.”

From Local Workshop to Global Force

The garage project scaled into a multinational business with a second office in Dubai, and expansion is underway in the United States. “Our typical customers are gym owners and future gym owners who come to us with a project or with a problem they might have that no one else knows how to solve,” says Kobal.

KingsBox caters to the dynamic needs of functional training enthusiasts and specializes in outfitting a wide range of training environments, from home gyms and personal studios to outdoor and commercial facilities. The modular, space-optimized equipment can be tailored for cross training facilities, fitness chains, and elite athletic teams.

Customization at Scale

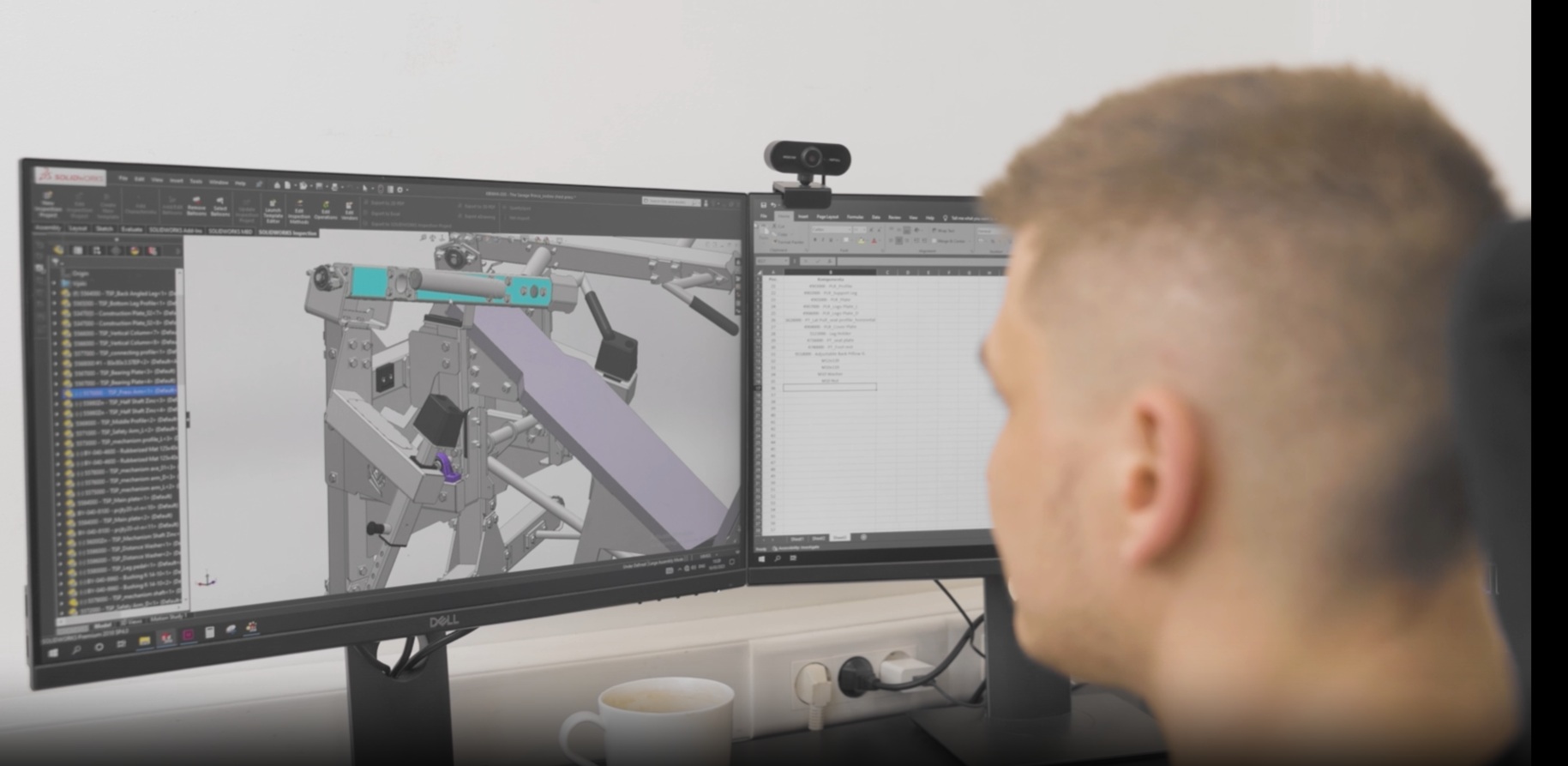

Managing hundreds of complex, highly customized projects a year demands a fast and precise design and manufacturing process. Industrial Designer Denis Štajdohar explains: “Each year, we complete up to 500 gym projects, each one involving over 1,000 individual components. At the same time, we also develop around 30 simpler products and about six more advanced strength-training machines.”

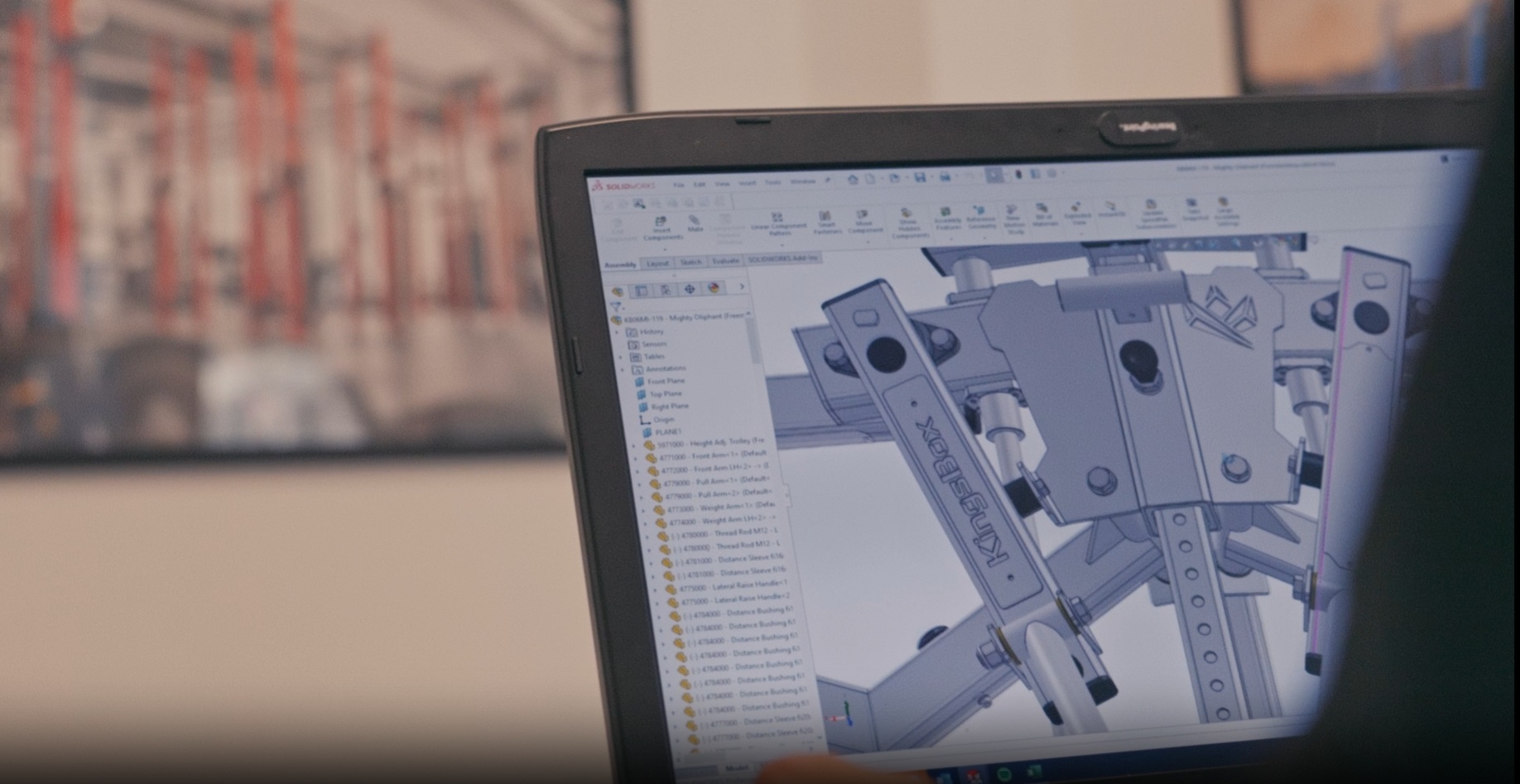

KingsBox relies heavily on Dassault Systèmes SOLIDWORKS to manage this vast workload. “SOLIDWORKS is the primary tool used by our development department and is essential for communication with our customers, as well as for sales and marketing,” says Štajdohar. “The user-friendly interface allows us to smoothly carry out all operations from 3D modeling and preparing technical documentation to exporting files and, most importantly, updating existing components.”

Customization is a key differentiator for KingsBox. According to Štajdohar, most of their products are custom-made for clients and can therefore be executed more quickly and easily using SOLIDWORKS. This flexibility has made the company a go-to partner for gym owners across Europe seeking personalized fitness environments.

Innovative and Reliable Partner

KingsBox thrives on innovation. “We are constantly thinking about how to simplify and speed up our development process,” Kobal explains. “This is where having a reliable partner like SOLIDWORKS plays a key role by providing innovative tools that enable us to keep up with market demand.”

To stay ahead of the curve, KingsBox recently upgraded its Dassault Systèmes SOLIDWORKS licenses to benefit from all the latest features and improvements. These improvements include a custom-developed plugin that automatically imports Bills of Materials (BOM) from SOLIDWORKS into the KingsBox ERP system. “This has enabled us to reduce errors and speed up the creation of bills of materials,” Kobal notes.

KingsBox’s equipment, largely composed of steel components, welded assemblies, and sheet metal, is designed using a variety of SOLIDWORKS tools. “The functions we use in the SOLIDWORKS environment include 3D modeling, sheet metal, and weldments, and of course, the tools for preparing technical documentation,” Štajdohar explains.

Simulation Optimizes Product Performance

KingsBox has also adopted SOLIDWORKS Simulation to improve product performance and user safety. “We have started using SOLIDWORKS Simulation, specifically Motion Study, which allows us to test and develop load curves as we design strength training machines,” says Štajdohar. Load curves show how a machine’s resistance or applied force changes at different points during an exercise’s range of motion. “With this feature, we can predict how the machine or load will affect specific muscle groups, as well as assess its functionality and ergonomic suitability.”

This advanced simulation is helping KingsBox push the limits of what’s possible in fitness equipment, ensuring that its machines are not only robust but also optimized for real-world use.

A Philosophy of Growth and Respect

KingsBox’s success stems from more than just great products. It’s driven by a clear mission and values: to provide a space where people can grow into the best version of themselves in a world where everyone has the tools and support to reach their full potential.

Internally, the company promotes a culture of innovation and ongoing learning. Team members are actively encouraged to expand their knowledge, build new skills, and advance their careers. With a shared sense of curiosity and motivation, the company believes there’s no limit to what it can achieve.

KingsBox also credits much of its growth to its long-term partnership with SOLIDWORKS. “We have been working with SOLIDWORKS for seven years, and we are delighted with their service, and we definitely recommend them to others,” concludes Štajdohar.

If you would like to raise the bar for product development at your company, contact your local reseller to learn more about SOLIDWORKS.