Building Doc Ock: How Tyler Csatari Turns Fiction Into Function

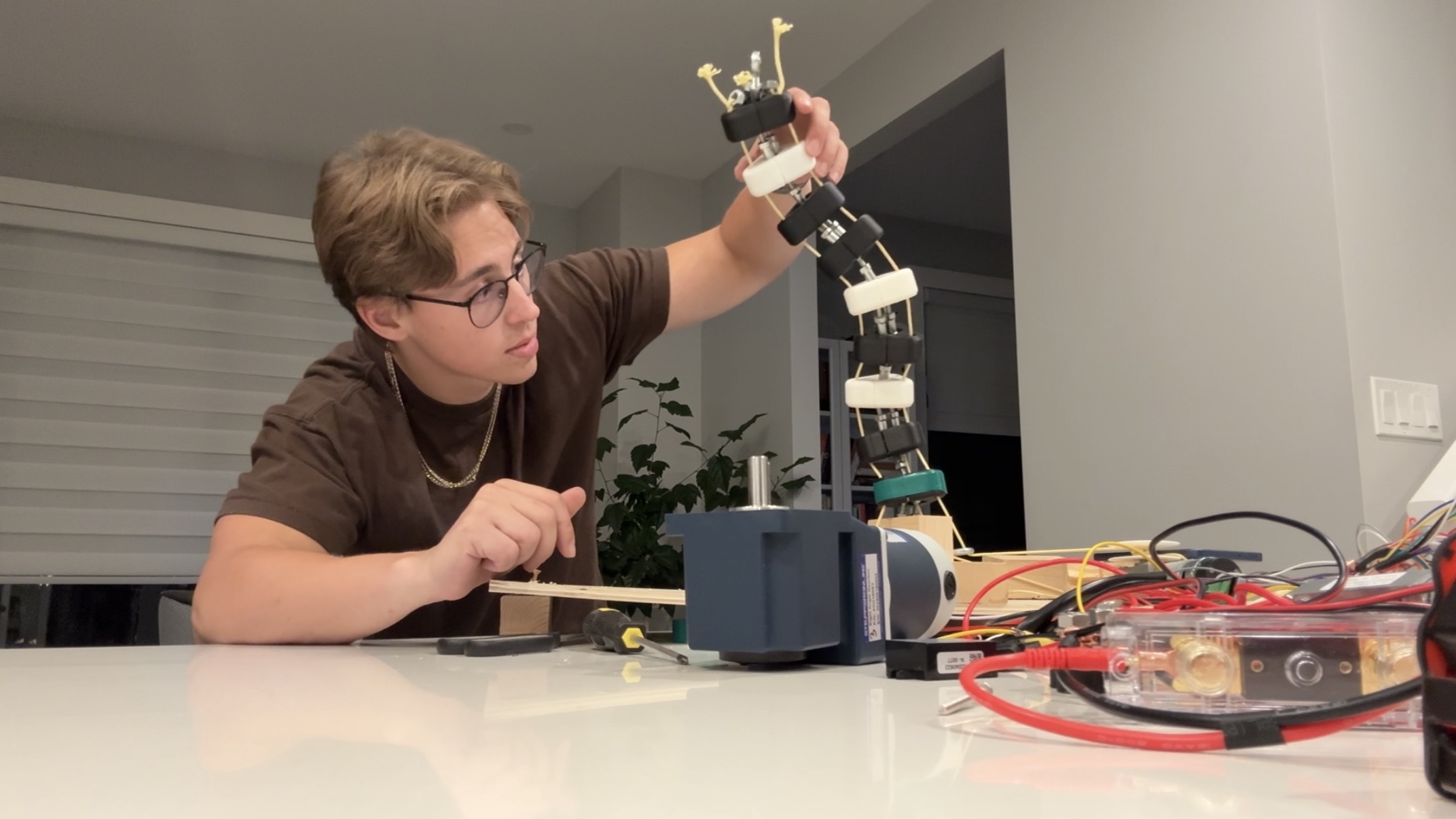

Every October, most people dig through closets for old Halloween costumes. Tyler Csatari opens a CAD file. This year, his “costume” includes 12 motors, custom 3D-printed vertebrae, and four mechanical arms that move under motor control. He’s building his own version of Doctor Octopus, one of Spider-Man’s most unforgettable villains, offering an ambitious costume ideafor makers who love engineering cosplay.

Why Doc Ock Still Fascinates Us

Doctor Octopus, or Otto Octavius, has always stood out among comic book characters. He’s the genius who built something incredible and paid the price for it. In Spider-Man 2, his robotic arms amplify his strength and precision, but they also turn on him. The story balances invention and obsession, the dream of building something powerful, and the risk of losing control over it.

Tyler has been fascinated by comic book characters and the concept of practically recreating their powers since he was a kid. “[Doc Ock is] an engineer who went too far,” he says. “There’s something relatable about wanting to see if you can make the impossible real. That combination of ambition, curiosity, and danger makes Doc Ock an exciting challenge. The character’s technology feels grounded in reality: the mechanical arms, the torque, the wiring, all things that could exist with enough skill and patience.”

Tyler calls his creations “technical cosplay”, or as he puts it, “practical cosplay.” It’s where costume design meets real mechanics, offering practical cosplay ideas for makers who want to bring characters to life. The goal isn’t just to look like a character on screen, but to make the gear work. With Doc Ock, Tyler is testing how far that idea can go – a Halloween project that moves, lifts, and reacts like something out of the film.

Extreme Challenges to Creative Fabrication

Tyler’s audience first found him through online challenge videos, a series of endurance tests, stunts, and experiments that required focus and problem-solving. Over time, the projects shifted toward making things. He started fabricating tools and props for his videos and soon realized that the build itself was the part he enjoyed most.

“I didn’t have an engineering background,” he says. “But when I started 3D printing, I saw how powerful it could be. You can think of something, model it, and have it in your hands the next day.”

Tyler’s interest in 3D printing led him deeper into CAD and 3D modeling, which became the foundation for some of his most ambitious builds: a bulletproof Batman suit, a functional Iron Man armor, and now a working Doctor Octopus exoskeleton.

Engineering the Tentacles

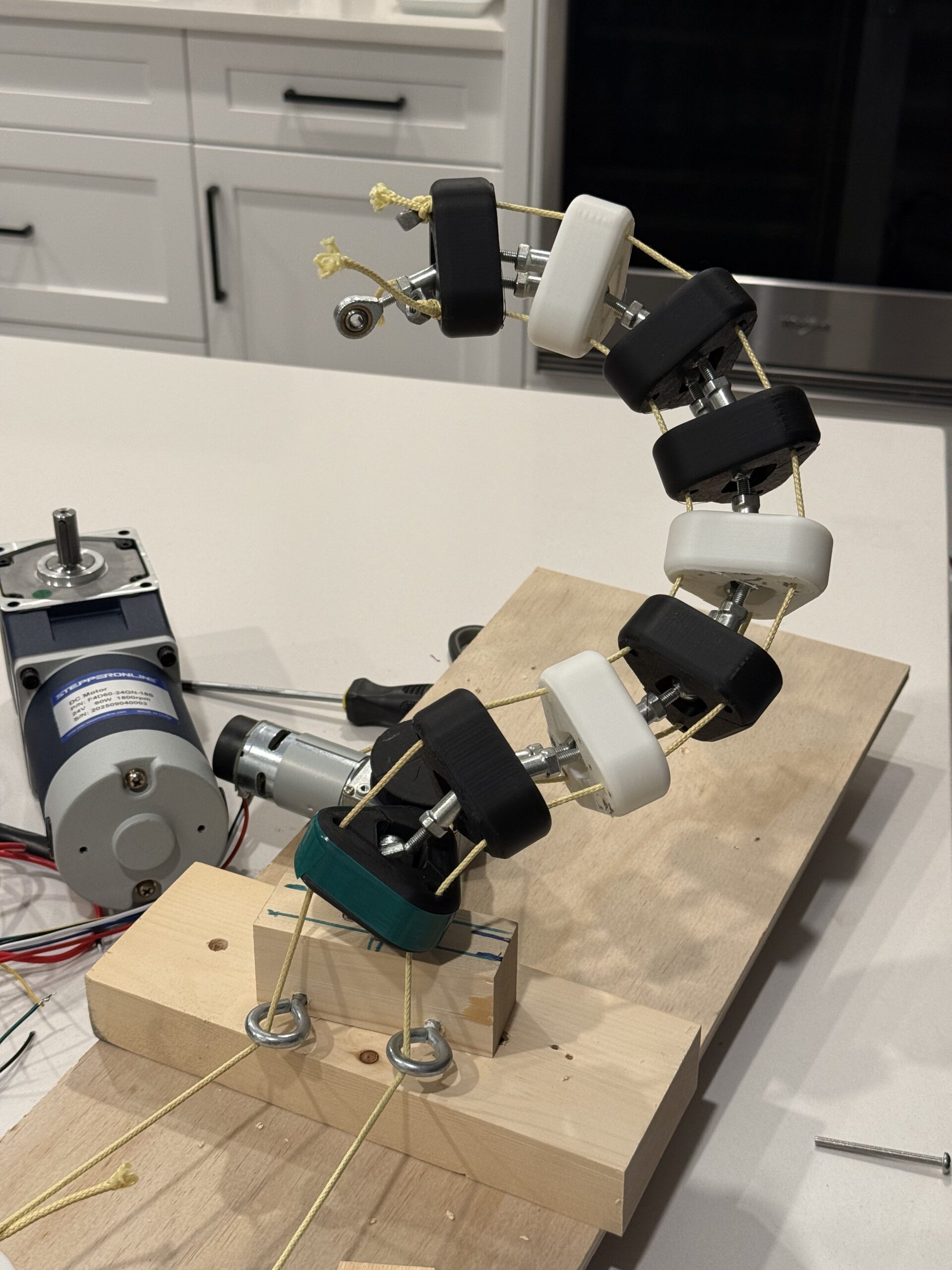

Each of Doc Ock’s four tentacles needs to move like a living creature: fluid, strong, and reactive, making it one of the most challenging Dr. Octopus cosplay designs to execute. Reproducing that behavior with real-world materials takes careful design.

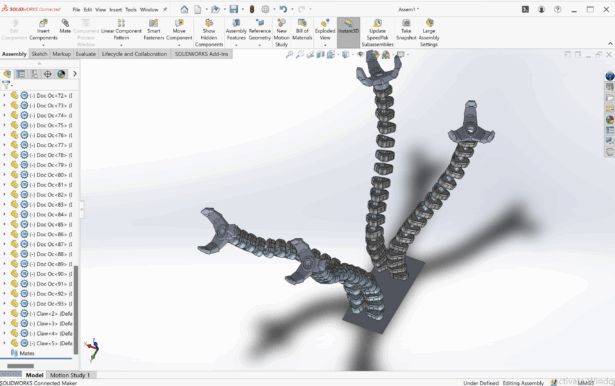

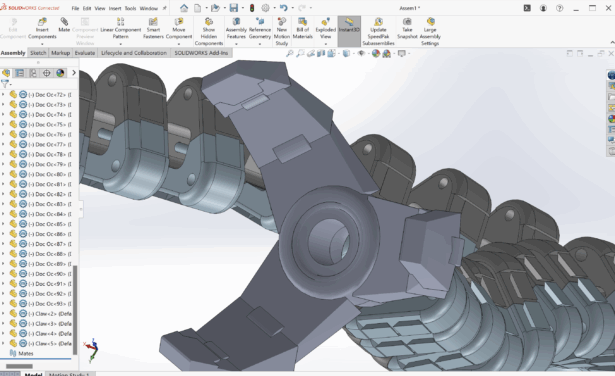

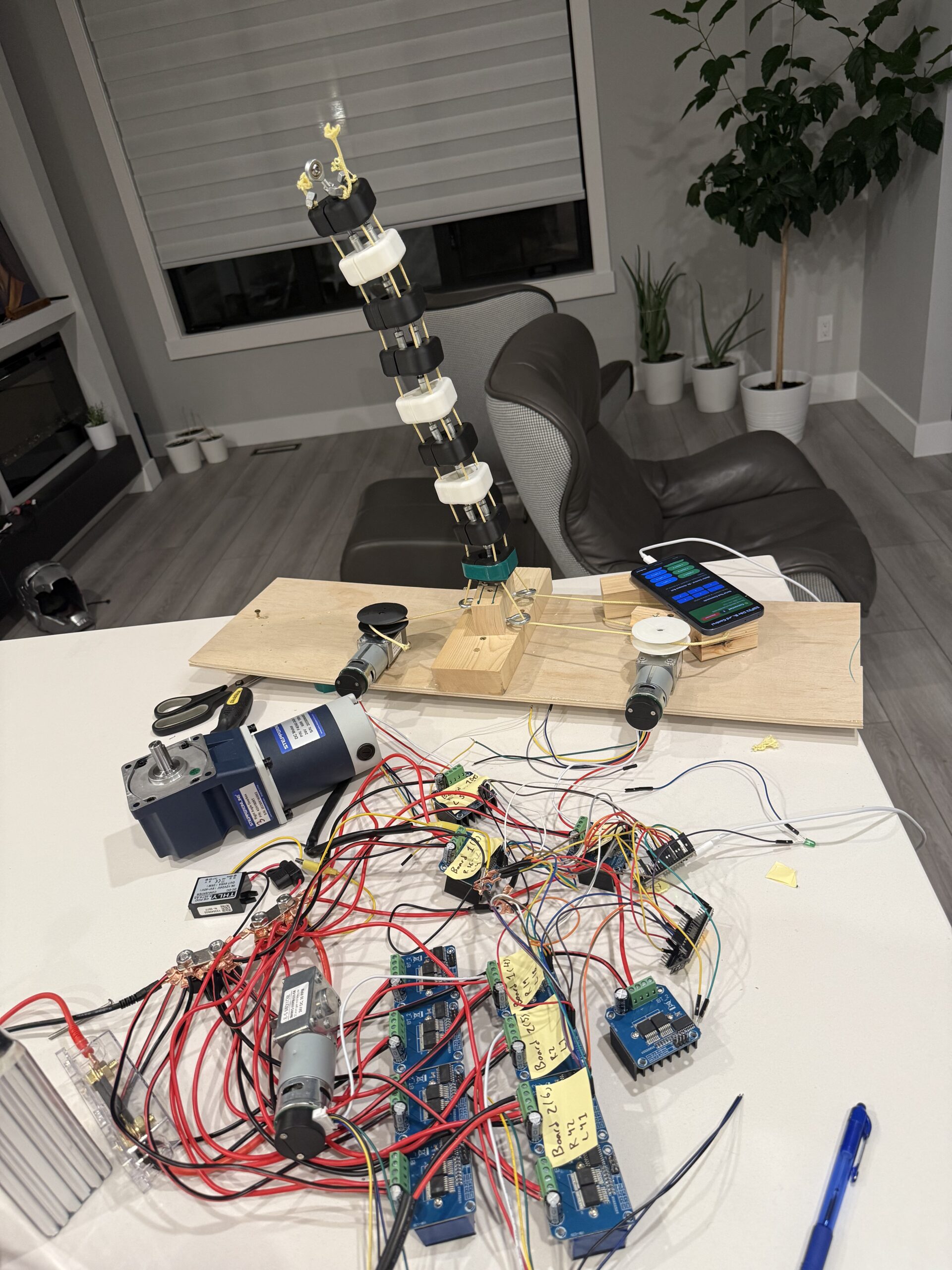

Tyler’s version uses a pulley-driven cable system instead of heavy motors at every joint. Kevlar rope runs through a chain of 3D-printed vertebrae, all connected to motors mounted on a backplate.

Each arm moves along three controlled cables, providing flexibility without excessive weight.

“The challenge is torque,” he explains. “The farther an arm reaches, the more force the base needs to support it. The pulley system helps distribute that weight and still gives the motion I want.” He modeled every component in SOLIDWORKS xDesign for Makers, refining hinge mechanisms, bearings, and mounting points before printing.

The Final Touches

Tyler’s mechanical design handles the functionality, but the additional visual details bring Doc Ock to life. The 3D-printed parts will be finished with metallic paint, and each claw will glow red from embedded LEDs, a small but unmistakable detail for fans who remember the movie.

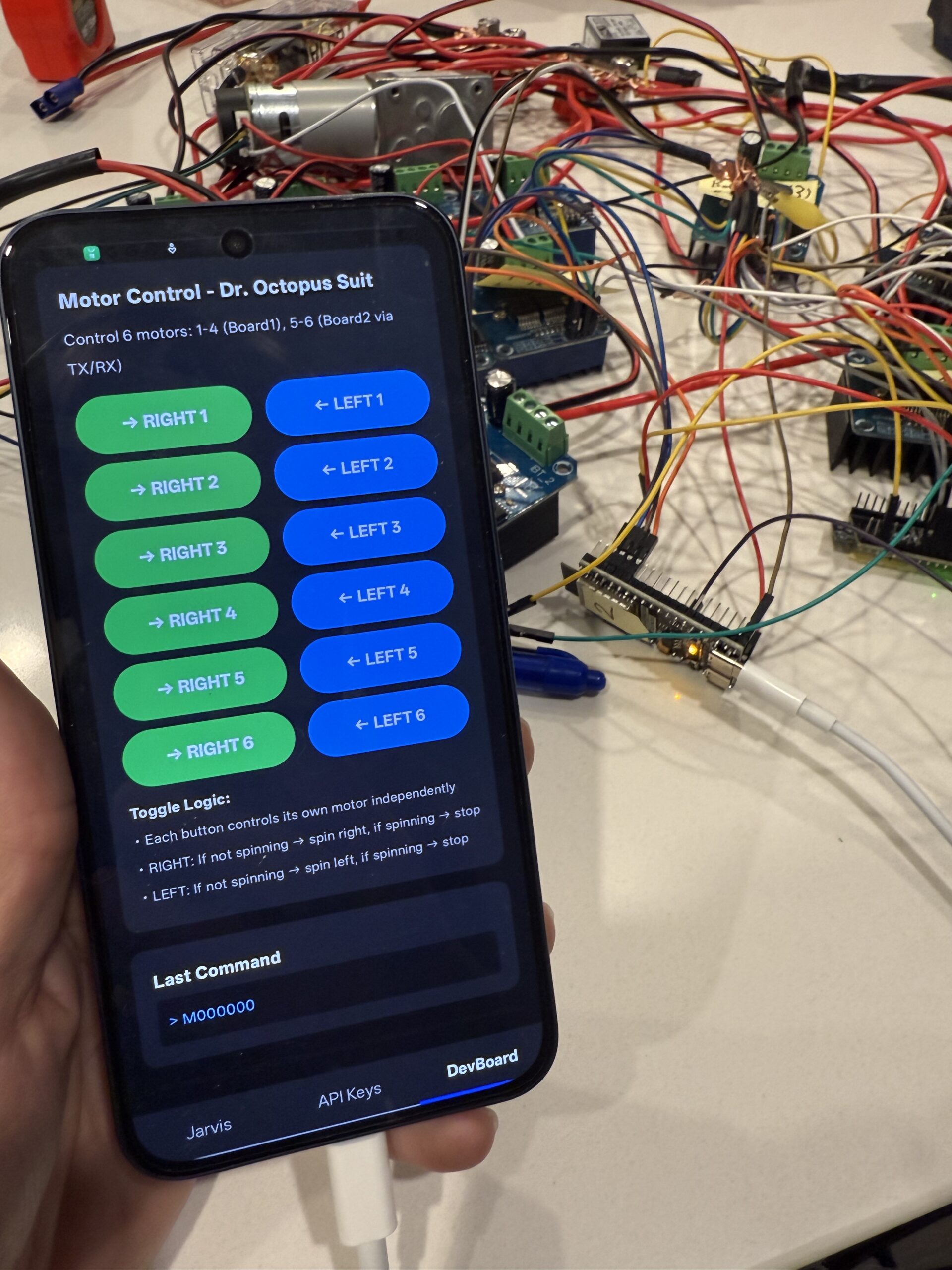

He also plans to connect the system to a voice-controlled program he wrote himself for a previous project so that Doc Ock’s arms can move on command. “It’s a mix of engineering and movie magic,” he says.

The Maker Mindset

Behind all the bells, whistles, and, in this case, motors, is a familiar driving force for many makers: curiosity. Tyler enjoys the process of seeing what he can create with the tools he has on hand and what happens when you push an idea to completion. “I like projects that sound difficult until you start them,” he says. “You learn so much by trying.”

Tyler happens to have a knack for envisioning possibilities with a few more motors than most of us. Whether you’re crafting props, building furniture jigs, or experimenting with robotics, SOLIDWORKS for Makers offers professional-grade CAD software to help you bring your cosplay costumes and other personal projects to life.

Learn more about SOLIDWORKS for Makers and start building your own original DIY cosplay creations.

Check out Tyler on YouTube, Instagram, and TikTok.