Material Options Now Greatly Expanded in SOLIDWORKS Sell

SOLIDWORKS is host to many appearances and materials that help your consumers (designers, students, CEO’s, etc) see how their products will look like in real life. Now, with a recent update, SOLIDWORKS Sell has implemented over 250 of those materials into its own library. Previously, the two programs had completely separate libraries. This was because the SOLIDWORKS library was native to the software and local on the computer; meaning that you couldn’t access the materials on one computer from another. Alternatively, the materials library for SOLIDWORKS Sell is located in the cloud and can be accessed from anywhere using a password and username. Due to this, people can access their templates, materials, and layouts from any computer. The addition of these materials has bridged the gap between the two programs and allows for an easier transition between the two. This allows for 1-1 mapping from local to online materials. Meaning they maintain their integrity in standard and high definition renders, and even in AR.

Before this update, the SOLIDWORKS model came in with a flat grayish texture that always needed to be changed for every single group ever uploaded. Then, you would have had to go through the extensive materials library in order to find a material that might have been close to what you had before. If you didn’t find one that fit your needs, you would have had to create a new material. This includes finding a high-definition image that mapped to the geometry correctly, and fiddling with its settings in order to get what you wanted. Minutes turn to hours and you finally have a decent looking product that resembled your SOLIDWORKS model.

Now the process has been streamlined. All you need to do is determine and assign the material natively in SOLIDWORKS and the rest is taken care of. This means that when you assign one of these materials to a geometry in SOLIDWORKS, then the material will already be assigned to that geometry in SOLIDWORKS Sell.

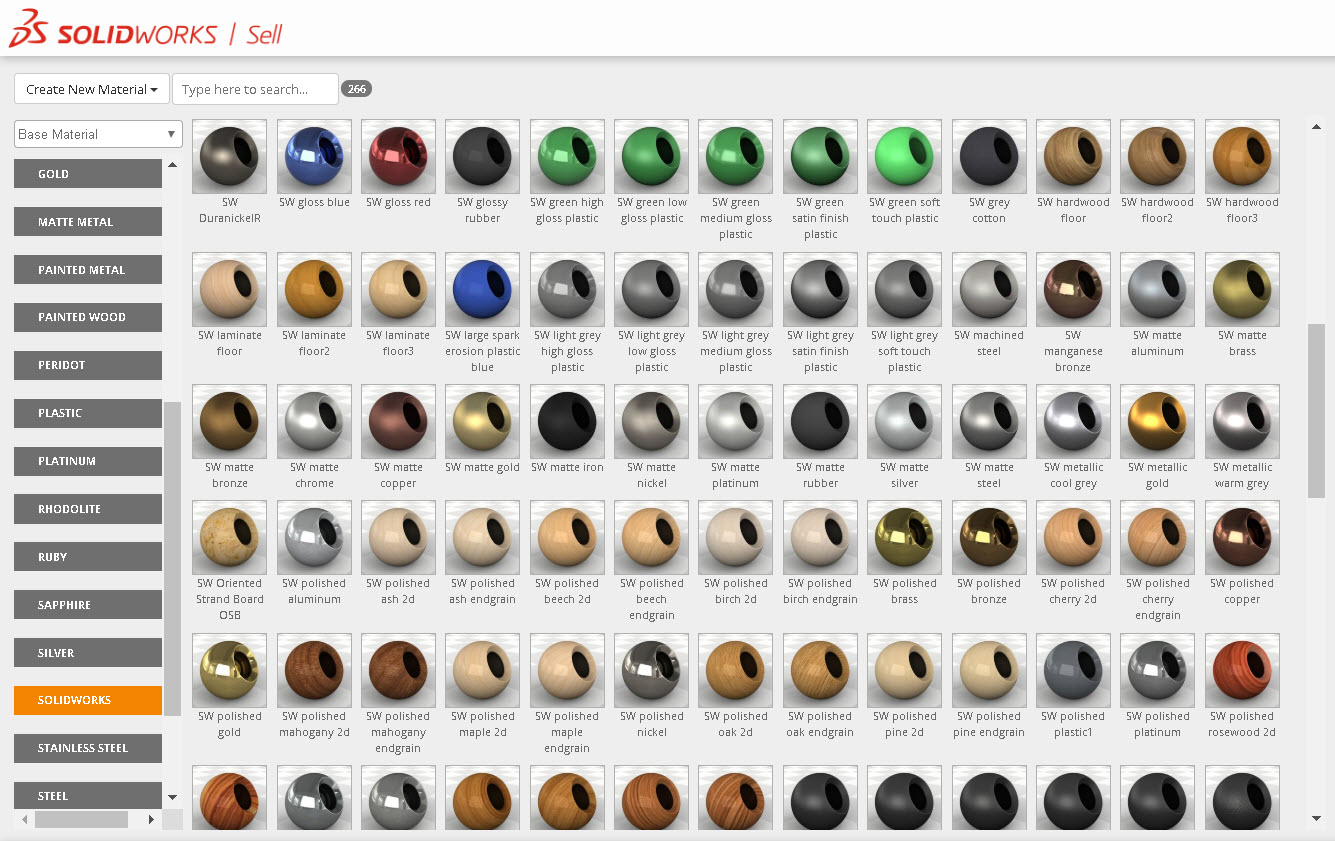

Finding them is simple; all of the new materials are prefixed with SW for SOLIDWORKS. Therefore, by going to the materials library and searching for SW, or selecting the SOLIDWORKS base materials, you’ll be able to see all 266 of the materials added; a sample of which can be seen in Figure 1 below.

While these don’t include user customized materials yet, there is still a considerable variety of metals, plastics, wood and more. Not only do these materials include regular base materials like oak or iron, but many of the materials added have several finishes available. Plastics include high, medium, and low gloss, along with satin finish and soft touch. Metals can be brushed, burnished, polished, or have a powder coat applied. The capabilities are almost endless. Now, consumers don’t have to spend the time to manually re-create materials because the SOLIDWORKS SW materials will be there waiting for them.

Here is an example of it in action. Figure 2 showcases how easy the transition is between the two programs. None of the materials were changed on this coffee maker after it was published to SOLIDWORKS Sell, and the two models are almost identical. With a single click of a button, the model transitioned seamlessly from parts and assemblies in SOLIDWORKS, to configurable parts and groups in SOLIDWORKS Sell. Also in figure 2, it showcases high quality renders taken from each of the programs and the coffee maker that are still indistinguishable.

The addition of these materials can cut the time, money, and effort spent perfecting and setting up a model for a website. Now, you can have a good looking product within minutes of publishing a model to SOLIDWORKS Sell.

Check out the video tutorial showcasing this new feature:

Keep up with the frequent updates on the SOLIDWORKS Sell Forum page.