3D Printing – The First Layer

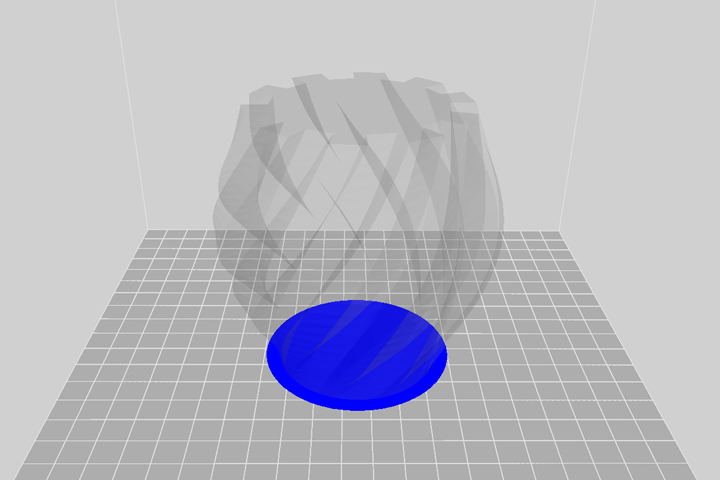

RaftsThe purpose of a raft is to sit in between the build platform and your part. Doing so assists with the bed adhesion and prevention of warping. Rafts are often used when printing in ABS. Rafts can also be used to help stabilize models with smaller footprints, creating a stronger foundation upon which your printer can build the layers of your part. Once your print is complete, the raft should peel away from the print and can be discarded. Advantages

Disadvantages

|

|

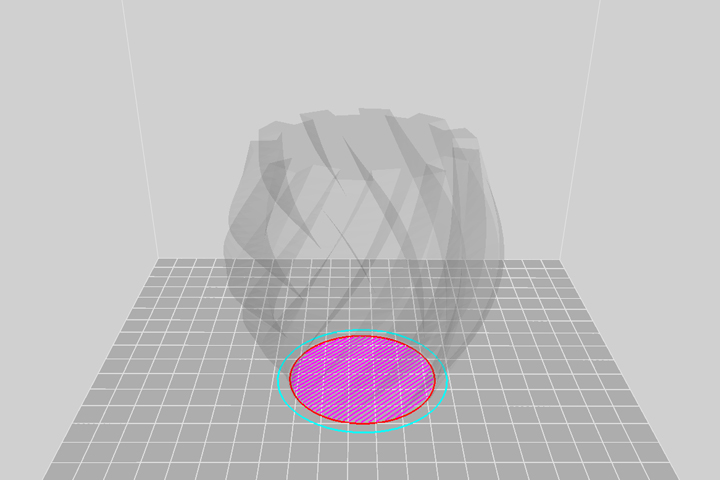

SkirtsA skirt is an outline that surrounds your part without touching. The skirt is printed before the first layer of the part, helping to prime the extruder and establish a smooth flow of filament. A skirt also allows you to detect and adjust any leveling or adhesion issues before the part has started to print. Advantages

Disadvantages

|

|

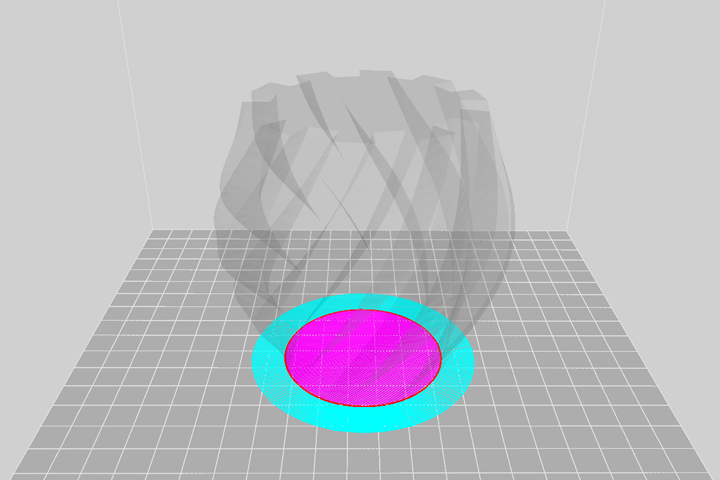

BrimsA Brim is similar to a skirt however, unlike a skirt a Brim is attached to the part. Typically, a brim would be printed with an increased number of outlines, creating a large ring around the part. The reasoning behind this is to help hold down the edges of parts, preventing warping and assisting with bed adhesion. This can also help with the stability of your print, widening the bed contact area. Advantages

Disadvantages

|

|

Glossary of terms used:Warping: This occurs during a print when the material shrinks as it cools, resulting in the corners and other parts of the print to lift and detach from the build plate. Bed Adhesion: Ensuring the print is fixed in place on the print bed and will not come unstuck during the print. |

Find out more about 3D Printing and the best 3D Printers on offer here.