Starting Your Journey to Sustainable Product Design

Take a look around the next time you go shopping. There is a movement towards doing more with less, with minimalist packaging and products promoting energy savings, and more sustainable products overall. For instance, I was looking at my laundry detergent and the bottle stated what the company was doing to meet their sustainable goals. Also, if you look at dryers, you’ll notice many manufacturers are marketing energy star ratings, energy consumption and efficiency. But it’s not just consumer products that are ‘leaning in’ to sustainable practices, the architecture industry is also partaking as buildings can get rated based on sustainability factors.

Based on the attendance at my 3DEXPERIENCE World session, “Starting Your Journey to Sustainable Product Design,” it looks like many of you are interested in sustainable design. For anyone who missed my session and is curious, I’ve got some tips on how to help you get started.

Sustainable product design focuses on minimizing environmental impact throughout a product’s life cycle while maintaining functionality and value. The best approach follows circular economy principles, aiming for durability, recyclability, and resource efficiency. The idea is to do more with the least amount of resources during the product’s entire life cycle. That goes beyond minimizing material usage, but also considering things like the cost of transport in terms of environmental impact and how things are manufactured, for example. Beyond measuring carbon impact, is what I call the three R’s: the right to repair, the right to upgrade, and the right to down cycle.

I know you’re asking, but how much more will this cost me? Think of it this way: You’ll have a competitive edge, spend less on materials, and be a leader in the movement, all while reducing your impact on the environment.

You can do a whole lot before you have to think about investing or changing your process. Most of sustainable design is a change of outlook and changing the way think about solving a problem.

Are you ready to join the movement and start your sustainable journey? To get started, I propose taking these six steps to take into consideration:

- Sustainable Material Selection

- Energy Efficiency & Low-Impact Manufacturing

- Design for Longevity & Repairability

- Circular Economy & End-of-Life Considerations

- Ethical & Sustainable Supply Chain

- Lifecycle Assessment (LCA) & Certifications

- Sustainable Material Selection

I remember when I was living in the States, and the NEST thermostats came out. Everyone was replacing their old thermostats and using NEST to optimize their home comfort and minimize their bills. The unintentional downside was that the old thermostats were being thrown into the dump. The problem was the old thermostats had mercury in them, an incredibly poisonous material which has to be kept out of the ecosystem. So, it’s important to educate people on how to properly dispose of old items when you launch game-changing products.

During my research for my World presentation, I looked at how the headphone industry was taking part in sustainable practices. For example, for the frame and frame and housing, you could use aluminium, stainless steel, recycled plastic, or maybe wood for aesthetic purposes. Then for the cushions and headband and padding, you could use vegan leather, natural rubber, organic cotton, lots of materials like that are more sustainable. And consumers aren’t going to shy away from the cost if it’s higher than the cheaply made, non-eco-friendly versions, as it’s a small price to pay to reduce waste in the environment, all while rocking a rad-looking product.

Here are a few sustainable materials to consider:

Recycled & Renewable Materials

- Use recycled aluminium, plastics, and rare earth metals to reduce mining impact.

- Explore biodegradable plastics or plant-based materials where applicable.

Toxic-Free Components

- Avoid lead, mercury, and brominated flame retardants (BFRs).

- Comply with RoHS (Restriction of Hazardous Substances) regulations.

Electronics and Circuitry

- Lead-free, RoHS-compliant components – Source from Digi-Key, Mouser, or Fairphone-certified suppliers.

- Low-energy Bluetooth chipsets – Qualcomm or Nordic Semiconductor offer power-efficient SoCs. Battery & Sustainability

- Swappable, replaceable batteries – Avoid glued-in batteries. Consider solid-state or graphene-enhanced cells.

- Sustainable battery suppliers – Northvolt (EU) or Aceleron (modular battery solutions).

Material choices can have a long-term impact on the entire product life cycle. Less material equals less cost to make and manufacture.

- Energy Efficiency & Low-Impact Manufacturing

I can tell you from experience that designs are getting better at reducing energy usage. I remember when I bought an Apple iMac computer in 1998, and it had a CRT screen which took 35 watts. Today, we have flat screens that take 0.9 of a watt.

We also have to consider the energy that’s consumed in the manufacturing process. 3D printing is good if you only have small numbers to produce. It’s relatively energy-efficient, but it’s too slow for large production.

Here are some factors to consider for energy usage and manufacturing:

Efficient Design

- Use low-power processors and energy-efficient displays (OLED, e-ink, microLEDs).

- Implement adaptive power management for battery optimization.

Sustainable Manufacturing Practices

- Reduce water usage and carbon emissions in production.

- Use renewable energy sources in factories.

Efficient Battery & Power Management

- Use low-energy Bluetooth 5.0 or higher for extended battery life.

- Implement auto power-off and energy-efficient chipsets.

Sustainable Manufacturing

- 3D printing for reduced waste

- Use biodegradable filament (PLA, PHA) for rapid prototyping

- Use solar-powered or carbon-neutral factories.

- Find ethical manufacturers in Taiwan or Europe or Fairtrade-certified plants in China.

- Minimize water and chemical usage in production.

- Lean manufacturing techniques – Reduce excess material waste during production.

- Design for Longevity and Repairability

Remember when you could repair a TV? I may be dating myself, but back in the day, you would call someone who could replace a module or component. Unfortunately, today, things break and get thrown away. We want to move away from the consume-to-trash ideology and move towards a consume, re-purpose, and recycle design philosophy. There will still be some stuff going to waste, but we want to reduce that as much as possible.

Think of designing things that can be serviceable. Even if you have to spend a little bit more on the design upfront and move from a consumable product to a value product you; can upgrade your position in the marketplace.

Consider the following options when designing for longevity and repairability:

Modular & Repairable Design

- Use standardized screws instead of glue for easy repairs.

- Design swappable batteries, upgradable RAM/storage, and replaceable parts.

- Follow Right-to-Repair principles to allow consumers to fix products.

Durable & Timeless Aesthetic

- Avoid planned obsolescence by ensuring hardware and software longevity.

- Use scratch-resistant, durable materials to extend product life.

- Circular Economy & End-of-Life Considerations

In a circular economy, the primary goals are to eliminate waste from the system, minimize or exclude the use of natural resources, and design and manufacture products that have a longer life cycle or multi-use life cycle.

Think of it as designing for disassembly. Here are some things to consider:

Recyclability & Responsible Disposal

- Ensure easy disassembly for recycling (no mixed-material components).

- Partner with e-waste recycling programs for proper disposal.

Trade-In & Refurbishment Programs

- Implement buy-back and refurbishment programs to extend product life.

- Encourage reusing components in newer models.

Biodegradable & Minimal Packaging

- Use compostable or recycled cardboard instead of plastic.

- Reduce packaging size and use soy-based inks for printing.

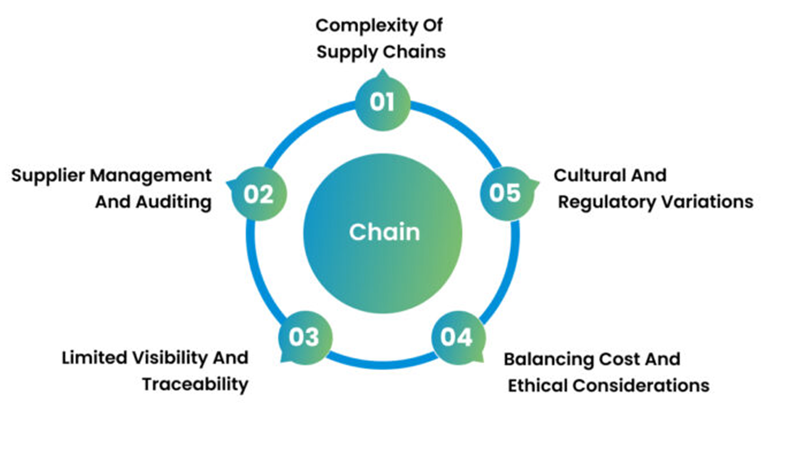

- Ethical & Sustainable Supply Chain

Where and how you source and manufacture things is equally important. Here are some things to consider:

Responsible Sourcing

- Use Fairtrade-certified suppliers for rare earth metals.

- Avoid conflict minerals by sourcing ethical cobalt, lithium, and gold.

Carbon-Neutral Logistics

- Reduce emissions by using regional production centers.

- Opt for low-carbon shipping options like sea freight instead of air freight.

Eco-Friendly Logistics

- Ship in compact, lightweight packaging to reduce emissions.

- Use carbon-offset shipping methods.

- Lifecycle Assessment (LCA) & Certifications

There’s a saying, “If you can’t measure it, you can’t improve it.” Once you’ve implemented the first five steps, I’d urge you to do a Life Cycle Assessment (LCA) to measure the environmental impact of those steps. An LCA is a systematic method used to evaluate the environmental impacts of a product, process, or service throughout its entire life cycle. It helps identify areas for improvement in sustainability by assessing energy use, emissions, waste generation, and resource consumption at each stage.

Here are some steps you can take to measure your success:

Measure & Reduce Carbon Footprint

- Conduct a Lifecycle Assessment (LCA) to analyze the impact from production to disposal.

- Optimize design choices to reduce emissions and resource use.

Eco-Certifications & Compliance

- EPEAT Gold, Energy Star, RoHS, and TCO Certified for sustainability.

- Communicate transparency on sustainability efforts to customers.

When you do sustainable design, even without doing any sort of life cycle checks, you can go through some or all of these steps to make a difference.

Why should you care?

Not only will you be saving the planet, but you can also win and retain customers, comply with increasingly strict regulations, and save on production costs.

Plus, all the cool kids are doing it. While conducting my research, I found many companies practicing sustainable design and manufacturing practices, including three headphone designers. Some other cool examples I came across were 3D-printed engine components made from recycled titanium tested by Rolls Royce, HP’s PC with recycled coffee grounds and post-consumer recycled and ocean-bound plastics, and a new sports performance and GPS watch designed from day one to be repairable and upgradeable throughout its long life. How cool is that? With Earth Day approaching, I hope you’ll be inspired to start your journey today.

You might also be interested in these blogs:

Is Your Design Sustainable? Sustainability and Circular Design Part 1

Sustainability and Circular Design Part 2

Discover Your Ultimate Toolkit for Eco-friendly Parts