MRP vs ERP – What’s the Difference?

Modern products are becoming more complex exceptionally fast, with a typical new car having over 100 million lines of code, according to the MIT Technology Review. It’s common to find that 60% or more of a new product’s components are from suppliers and production partners outside the company. For engineer-to-order manufacturers, it’s close to 75% or more.

It’s undeniable that manufacturing operations are getting more complex. But what’s the solution? Two types of systems often come up: material requirements planning (MRP) and enterprise resource planning (ERP). Both can transform how you manage production.

So how are MRP and ERP similar? And how are they different? Let’s dive into the full details of ERP vs. MRP.

What Are ERP and MRP Systems? A Brief History

Material requirements planning started in the 1960s as a way to help manufacturers calculate what materials they needed and when. Many manufacturers got their start producing the same product using components they sourced locally or made themselves. Customers weren’t given the option of customizing products. The core process areas of bills of materials (BOM), inventory tracking, and master production scheduling dominated global manufacturing. Automating these three areas became the foundation of MRP.

However, global competition became fierce fast, forcing manufacturers to rely on price and availability to win more sales. Offering more customized products and capitalizing on customers’ ideas helped manufacturers escape the price wars. More feature-rich products that often needed services also required a new production system, and manufacturing resource planning (MRP II) was born.

A Different MRP: Manufacturing Resource Planning

MRP II is a system built around the original MRP that also includes production planning, master production schedule, and capacity requirements planning as well as required financial capabilities such as accounts receivable and accounts payable. Once the planning phase is complete, and the plans have been accepted as realistic and attainable, the execution functions come into play. These include the shop floor control functions of input/output measurement, detailed scheduling and dispatching, as well as anticipated delay reports from both the shop and vendors, purchasing follow-up and control, and other functions.

MRP II was perfect for the expanding world of manufacturing that had become heavily dependent on suppliers. In today’s discussions of ERP vs. MRP, most manufacturers use MRP to refer to the expanded MRP II capabilities, including not just raw materials but also labor, equipment, and other manufacturing resources.

The Evolution to ERP

To stay competitive, products have to be managed over their lifecycles, not just month to month to meet production targets. The financial implications of a changing production mix need to be predicted. Customer demand and supplier quality levels need to be factored in. Inventories need to be checked for availability. Every area of a manufacturing business needs to stay coordinated with production costs, direction, forecasts, and plans. That’s where ERP comes in.

ERP software connects your manufacturing operations with accounting, sales, customer service, human resources, and supply chain management in one integrated solution. While some companies still use standalone MRP solutions, many manufacturers find that ERP provides the comprehensive visibility they need to run their entire business efficiently.

Key Differences Between ERP and MRP

The most important thing to understand when it comes to ERP vs. MRP is this: MRP focuses specifically on managing your materials and production schedules, helping you know what to order and when. ERP takes a broader approach, connecting every department in your company from accounting to customer service.

Let’s go over the ERP and MRP differences in more detail so you can make the right choice for your business.

ERP vs. MRP Functionality

ERP functionality spans your entire business, connecting departments and processes that traditionally operated in silos. You can track a customer order from initial quote through production, shipping, and final payment, all within one connected solution. ERP includes modules for financial management, customer relationship management, supply chain optimization, quality control, and human resources, giving you complete visibility into every part of your business.

MRP functionality focuses specifically on manufacturing and materials management. You can plan production schedules, calculate material needs, track inventory levels, and manage bills of materials with precision. MRP answers questions like “What do I need to build this product?” and “When should I order materials to meet my production schedule?” However, MRP typically doesn’t connect directly with your accounting, sales, or customer service operations.

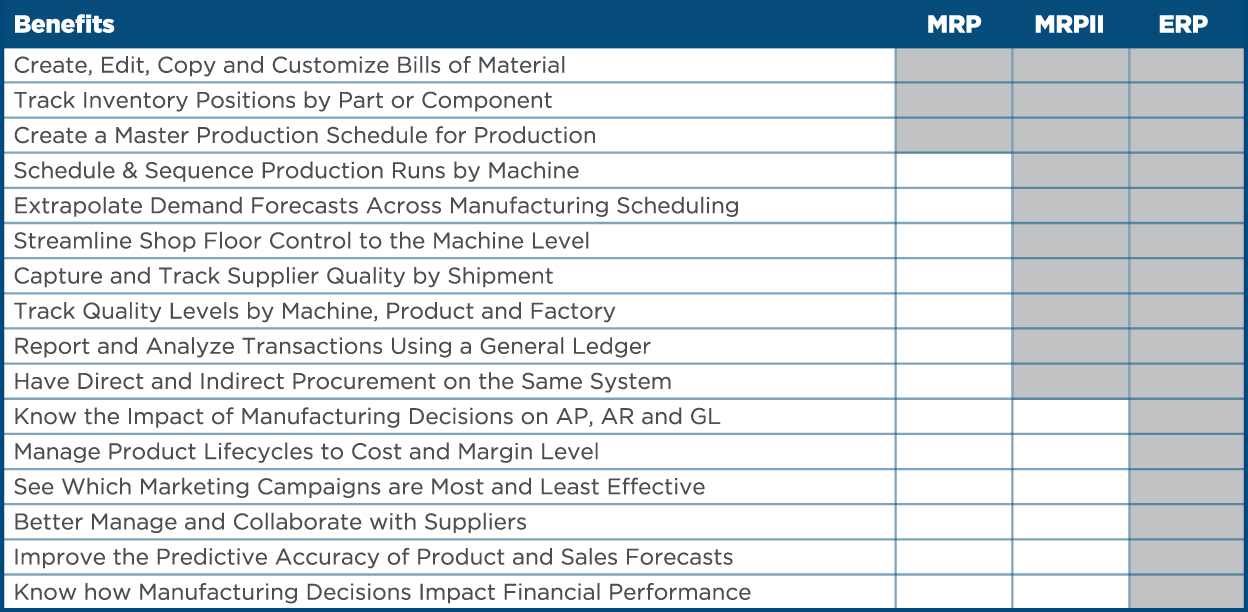

The chart below compares the different functionality of MRP, MRP II, and ERP:

ERP vs. MRP Users

ERP serves users across your entire organization, from executives who need financial reports to sales teams tracking customer orders to HR staff managing employee records. Your accounting team can see how production costs affect margins, your sales team can give customers accurate delivery dates, and your executives can make strategic decisions based on real-time data. ERP gives everyone the data they need to streamline their work and make better, faster decisions.

MRP users typically work in manufacturing operations, including production planners, inventory managers, purchasing agents, and shop floor supervisors. These professionals need detailed information about materials, production schedules, and capacity planning. MRP gives them the tools to optimize manufacturing efficiency, but it doesn’t extend that visibility to other departments in your company.

ERP vs. MRP Data

ERP data can include everything from customer information and financial transactions to employee records and supplier performance metrics. You can analyze relationships between different aspects of your business, such as how customer satisfaction correlates with on-time delivery or how supplier quality affects production costs. ERP also integrates with data from other applications like CRM systems and e-commerce platforms.

MRP data focuses on manufacturing-specific information like bills of materials, inventory management, production schedules, and supplier lead times. You get detailed insights into production efficiency, material usage, and capacity utilization. However, MRP typically operates as a standalone solution, which can create data silos.

ERP vs. MRP Implementation

ERP implementation involves your entire organization. You need to train users across multiple departments, integrate with existing business applications, and often redesign business processes to take advantage of the connected workflow. However, once implemented, ERP provides seamless information flow between departments and can adapt as your business grows and changes.

MRP implementation is generally faster and less complex because it focuses on a specific set of functions and training is limited to manufacturing personnel. Standalone MRP systems may not integrate well with your existing accounting, sales, or customer service applications. However, there are examples of MRP/ERP systems that work together, and these are often the best option.

ERP and MRP Integration: Working Together

While we often talk about MRP vs. ERP systems, it doesn’t have to be a competition. ERP/MRP software combines the best of both worlds by including robust materials planning capabilities within a comprehensive business management solution. This integrated approach gives you detailed manufacturing control and connects your production data with every other aspect of your business.

The definition of ERP/MRP systems centers on this unified approach to business management. Instead of managing manufacturing in isolation, you can see how production decisions affect cash flow, customer satisfaction, and overall profitability. Ultimately, that’s the answer to “What is ERP and MRP software?”: A complete business solution that treats manufacturing as an integral part of your entire operation rather than a separate function.

Eldon James: An ERP and MRP Example

To better understand the meaning of ERP and MRP, let’s look at what motivates manufacturers to change from MRP to ERP. It’s common for manufacturers to begin operations relying on Microsoft Excel for production scheduling and Intuit QuickBooks for their financials. But the more they become reliant on outside distributors and suppliers, the more the added advantages of ERP motivate them to migrate from MRP.

Eldon James is an example of a leading plastics manufacturer who chose to migrate away from basic MRP to the DELMIAWorks ERP system. What they were able to accomplish highlights the MRP vs. ERP difference:

- By having a single system that organized all the data they needed for production scheduling, quality assurance, and shipping, Eldon James was able to increase their on-time delivery accuracy. On-time deliveries happened 50% of the time with siloed systems that didn’t communicate. With DELMIAWorks ERP integrated across their operations, they soared to 98% – a jump of 96%.

- Reject rates plummeted from 30% to 2% as quality assurance had real-time monitoring to track where scrap was being produced in the production process. Like on-time deliveries, scrap rates and reject rates drastically improved when Eldon James had real-time data from the ERP system to manage production. Where and how scrap was being produced was no longer a mystery; the answers to the most challenging quality assurance questions were in the system anytime they needed them.

- The long-term goal of offering and producing over 6,000 products has been achieved. One of Eldon James’ strategic priorities is to always be innovating, always finding new ways to improve, and this includes their new product development strategies. With our ERP system in place, they are now offering over 6,000 products to their customers located in 40 different countries.

MRP vs. ERP Systems: What’s Right for You?

Designed for an era when mass production dominated manufacturing, MRP systems make factories efficient. But the greater the product complexity, the more integrated manufacturing needs to be across an entire business. The proliferation of new products, intensity of global competition, shorter time-to-market, and need for more cost control and visibility led to ERP platforms being created.

Choosing between ERP and MRP depends on your current business needs and future growth plans. Consider these key factors when evaluating which approach makes sense:

- Current pain points: Are your biggest challenges in manufacturing planning, or do you struggle with disconnected departments and manual processes across your business?

- Company size and complexity: Smaller manufacturers with simple operations might start with MRP, but growing companies typically need ERP’s comprehensive approach.

- Integration requirements: Do you need manufacturing data to connect automatically with accounting, sales, and customer service, or can you manage with manual data transfer?

- Budget and timeline: MRP implementations are typically faster and less expensive initially, but ERP provides better long-term value for growing companies.

- Growth plans: If you plan to expand product lines, add locations, or grow your team significantly, ERP provides the scalability you’ll need.

- Competitive requirements: Do your customers expect real-time order status, detailed quality documentation, or other capabilities that need integrated business processes?

Keep in mind that for many manufacturers, there is no longer truly an MRP and ERP difference. Integrating MRP into their ERP solution provides the best foundation for both current operations and future growth.

ERP and MRP from DELMIAWorks

So what is the relationship between ERP and MRP? At DELMIAWorks, we believe they should always work together. Having two different systems that aren’t in sync with each other quickly leads to problems including higher than industry average scrap rates, missed customer shipments, limited visibility and control of manufacturing costs, and more.

Today elements of MRP software systems are included in ERP software systems including material requirements planning, labor capacity planning, auxiliary equipment planning, machine and work center capacity planning, and rough cut capacity planning. Plus, with the advancement of ERP and MRP in cloud computing, combined solutions are becoming easier than ever to implement.

At DELMIAWorks, the discussion is no longer about ERP vs. MRP. Our manufacturing software fully incorporates MRP software and ERP in a single solution that connects material requirements planning with activities throughout your entire supply chain. Our MRP capabilities accurately and effectively manage all resources and requirements necessary to meet your manufacturing demand and maintain lean inventory levels.

The more adept manufacturers become using the MRP functional areas of their ERP systems, the more efficient their entire manufacturing process becomes—especially when relying on suppliers, partners, and distributors. Ready to see how integrated ERP and MRP can transform your manufacturing operation? Contact DELMIAWorks today.